Social media has given all of us access to our peers across the world in our related professional fields. Access to their opinions and thoughts – quickly and easily via a forum or by online posts. Among us in the reliability sector, it can be seen that the more progressive and enlightened thinkers tend to look deeper than the well-de ned and well-employed tools and techniques like FMEA, RCA, Pareto charts, Ishikawa diagrams, Weibull, design for reliability, and many others. They look at the people. Why? Because a lot of the tools and techniques fail to achieve their design intent, however diligently applied. But, it must be stressed, when the techniques fail, it is not always a people problem. It could be that the Path isn’t smooth enough. Or the Rider is confused. Or the Elephant doesn’t care enough.

Confused? Read on…

A general theme recently appeared in several postings in online reliability forums. People were talking about things like defect elimination, reliability improvement, and vibration analysis programs and things that work and things that have failed despite significant time and money investment. A few individuals developed the theme of behavioural issues and the refusal to change old habits. One suggestion urged people to read one book in particular: ‘Switch: How to change things when change is hard’ by Chip and Dan Heath. The essence of the book is not just about change; it is about what motivates people to do things and behave the way they do. It focusses on three cerebral aspects of a change problem: the rational, the emotional and the path.

The rational – they call it the Rider – is the side of the brain that has to be convinced that something is logically worth doing. Your tires are almost bald, it is rational to change them and therefore avoid affine and maybe an accident.

The emotional – they call it the Elephant – is the side of the brain that acts on emotional triggers. Your tires are bald, you have the kids on the back seats, and you imagine skidding across the motorway at 75mph and being in a five car accident – blood, bones and everything! That’s emotional.

The path – they call it the Path! – is where the environmental and situational factors have to encourage the change. The garage has just relocated from being 20 miles away on the edge of the city to being at the end of your street – it’s been made easy for you. The Path is now simple to navigate and smooth with no unnecessary obstacles.

The point is this: for a successful change to happen, all three have to be present. The Rider cannot direct the stubborn and heavy Elephant on his own – he will quickly be exhausted. And if the Path is long, complex or difficult then the journey (the change process) will not happen easily even if Rider and Elephant are motivated.

So, what’s this got to do with Condition-based Maintenance (CBM) reports? Well, from the perspective of a service provider it can be difficult to get a customer to take notice and implement recommendations in a monthly CBM report where you have identified problems and concluded that action is required. This is especially the case where you don’t have access to the CMMS and so cannot raise work notifications or orders. The need for action always seems to get lost in the swirl of reports, emails and meetings.

Actions or recommendations may stay open for months on end with no action taken. Whilst face to face meetings are always the best communication tool, we still need to send out CBM reports to maintenance planners, reliability engineers, engineering managers, technicians, and production people, i.e. the ones who can influence whether the work gets planned and scheduled or not. And a lot of this centres on the clarity and conciseness of the CBM report. It is an area where the majority of us CBM and Condition Monitoring Engineers can improve our reporting skills to increase the probability that action is taken.

Most of us have produced reports with confusing, jargon-filled paragraphs or one line sentences that did not inspire anyone to repair or replace equipment. It’s hard to be focussed when you are confused. A planning engineer is not going to understand the following: there is a non-synchronous peak at 3.11X and it has 1X sidebands which is indicates modulation, also there is a high RBPF which might suggest an electrical problem. Please inspect the equipment. Inspect what exactly?

The recommendation has to be presented at the right level to engage the reader and their mind. It has to motivate and force them into action with realistic and simple recommendations which alert their rational and emotional sides of the brain. Remember: Rider, Elephant and Path!

Over time – and since reading the book – I have re-adjusted my own approach to CBM reports and structured them into a simple format that focusses the Rider, awakens the Elephant’s emotion, and gives clear direction and a smooth path by dividing the small paragraph into three sections or sentences: The Problem (focusses the Rider); The Potential Consequences (awakens emotion in the Elephant); and The Recommendation (lets the Planner know what needs to be done – so they don’t have to think too much!) three sections or sentences: The Problem (focusses the Rider); The Potential Consequences (awakens emotion in the Elephant); and The Recommendation (lets the Planner know what needs to be done – so they don’t have to think too much!).

Here’s a typical report for a problematic pump:

- The Problem: High and destructive levels of horizontal vibration on the drive end bearings of motor and pump. The data indicates misalignment.

- The potential consequences: High risk of fatigue and catastrophic failure of bearings, coupling, seals, and shafts. Decreased long-term reliability and increased energy consumption.

- The recommendation: Raise a work order to precision align motor to pump. Also inspect coupling for wear or damage.

It’s only a small structural change to a report. But by appealing to the logic and the emotion of the brain it may start to accomplish its task with more engagement from Planning Engineers. A small change is often all that is needed as witnessed in much research and experiments in the book ‘Switch’. It’s clear that there are many more areas in the condition monitoring and reliability sector and beyond where behavioural change can be made to ensure the reliability improvement tools are successful. But to underpin this small change – from a CBM Engineer’s perspective – we need to understand that the engineer’s knowledge and experience is paramount to analyse the data, diagnose the problem and recommend the optimum solution.

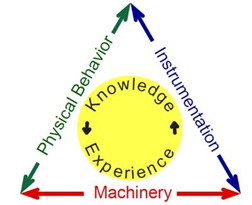

To be respected we must strive for knowledge and experience in three principal areas: machinery, instrumentation, and physical behaviour. It is suggested that all CBM and Condition Monitoring engineers follow the framework of Eisenmann and Eisenmann’s triangle (Machinery Malfunction, Diagnosis and Correction, p.1, 1997) to become a true expert in the domain. But in the meantime, if improvement or change is required to make you operations, techniques or maintenance organization more effective and efficient, remember the Rider, Elephant and the Path!

Autor: Jaime Borley

Ingeniero de Confiabilidad & Monitoreo de Condición

MSc en Ingeniería de Mantenimiento & Gestión de Activos (University of Manchester) BEng (Hons)

Ingeniería de Sistemas de Mantenimiento (Swansea Metropolitan University) Incorporated Engineer (IEng)

Miembro del Instituto de Ingenieros Mecánicos

Correo: jamieborley@yahoo.co.uk

0 comentarios